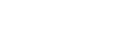

- Dynas Golf

- DYNAS ROYAL III

- MAN

- DR-III-MAN

- SHOT PEENING

Advanced Combative Distance

Combative Distance

AMORPHOUS METAL technology developed by KOLON, reduces the amount of backspin caused by increased velocity and decreased friction (roughly 400RPM ↓)

Adoption of a face with a thickness of 2 mm or less designed with our own technology (repulsion coefficient 0.92

The Power Curve effect increases repulsion effect

Guarantees an

accurate measurement

of even missed shots

Increased effective hitting area and sweet spot with 480cc head volume

Suppresses distance loss and directional shake in the event of a miss shot ( MOI increased by 15% compared to the previous model )

ROYAL exclusive shaft

created through

thousands of tests

Optimized for flying distance + high elasticity

Using high-strength, high - elasticity PAN- based 50- ton carbon fiber material, the softness and elasticity of the existing lightweight shaft are maximized simultaneously

Provides optimal and consistent trajectory after impact to achieve the best distance

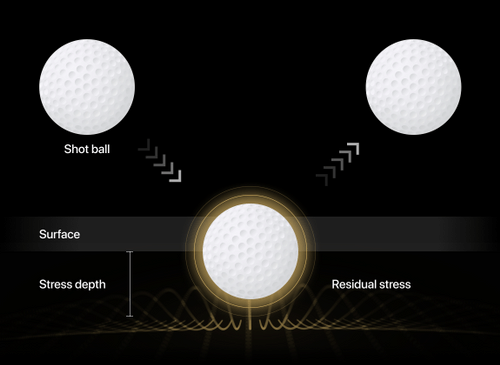

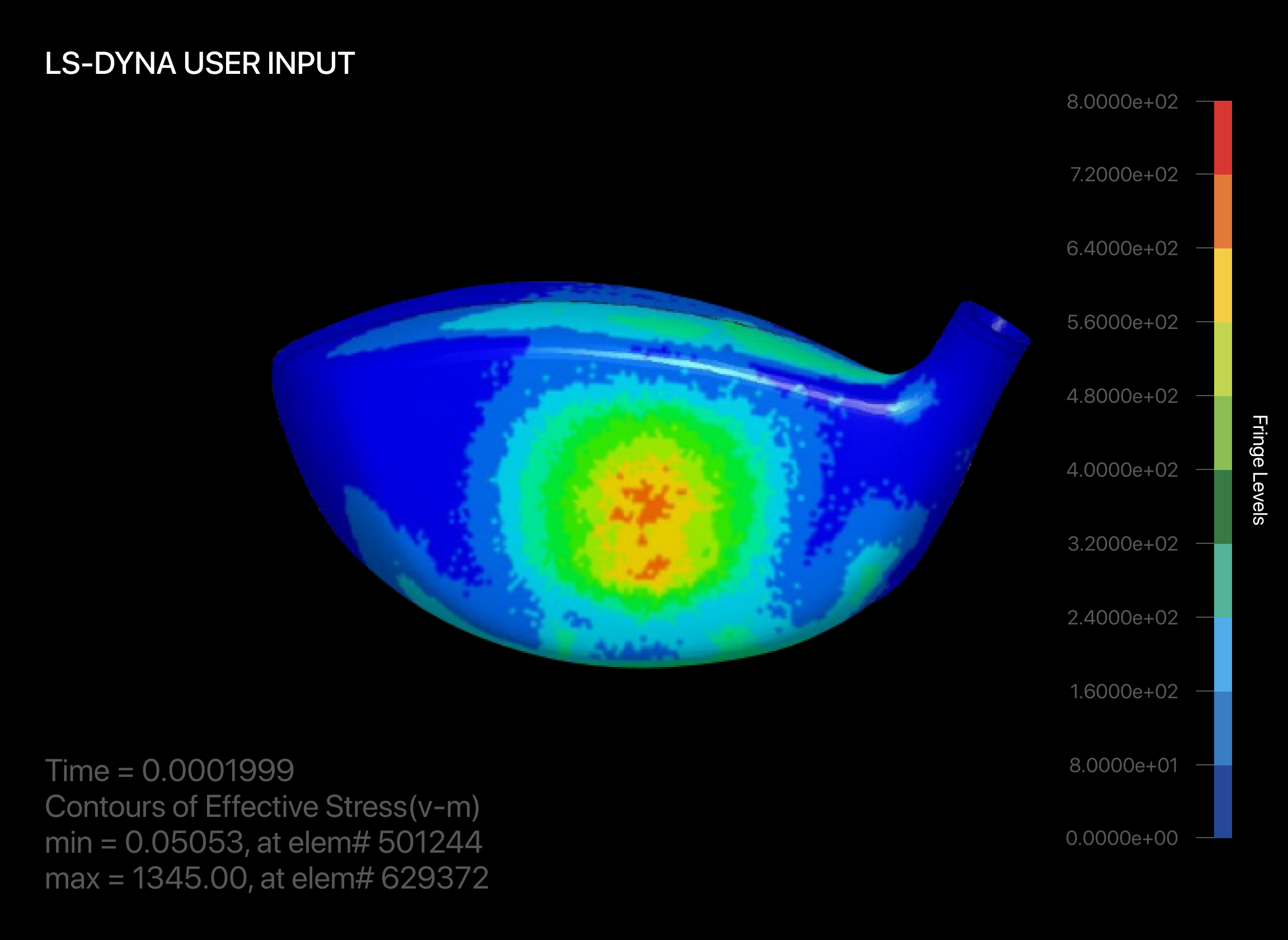

SHOT PEENING HEAD

What is SHOT PEENING ?

SHOT PEENING is a technology which maximizes the speed of the ball when it touches the club. Small spherical shots of less than 1mm bombards the surface of the head of the club. The surface compression stress strengthens the metal, and this ensures that the club will resist all fatigue failures.

Increased metal strength (improved durability)

equivalent to chrome plating

Increase in metal density

Removal of impurities from metal (improving elasticity)

Increased head elasticity

Reduce the amount of backspin

The impact energy transmitted from the golf ball is concentrated in the center of the face without being dispersed.

Distance Optimization Shaft

Shaft to increase head speed

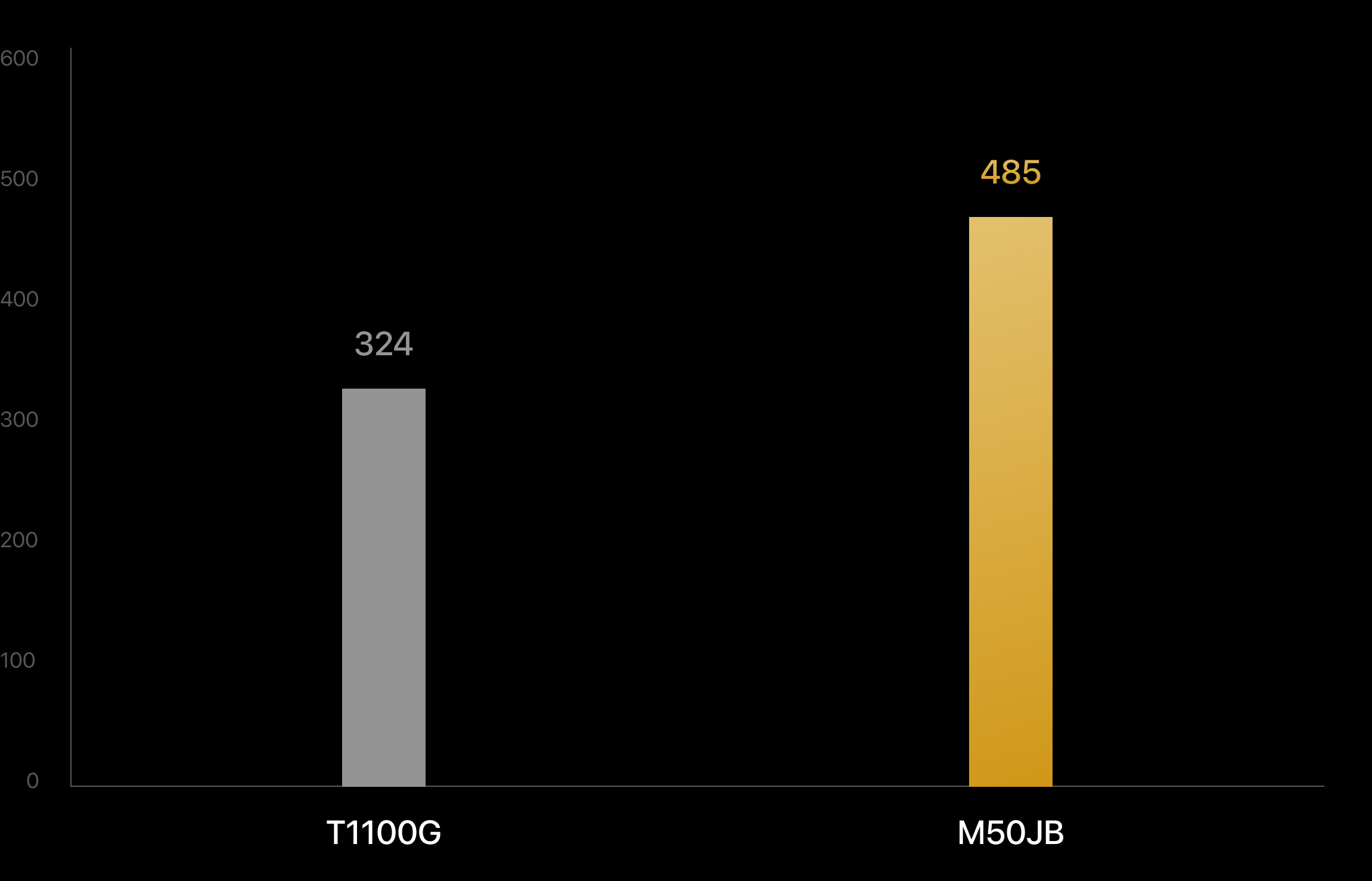

We use M50JB fabric which is 50% better than widely used TORAY's T1100G fabric

Shaft Structure and Effect

Super high elasticity super high strength carbon fiber

Increased tip stiffness

Reduces energy loss even in off-center hits by increasing the flexural rigidity of the tip

Optimal torque realization

By using a material with a high fiber content for the bias layer, a square impact is realized and ideal heating is realized

High vibration

High-strength material is adopted for the straight layer to realize high stability of the shaft

Elasticity comparison of fabrics [Gpa]

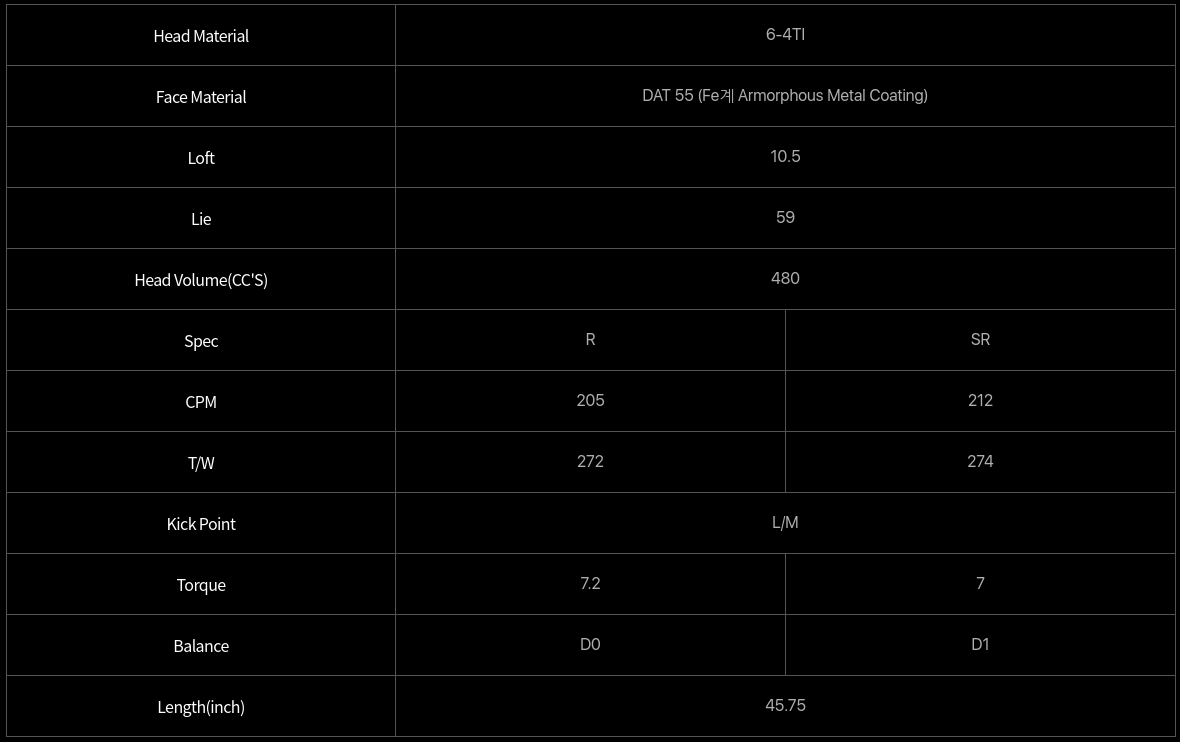

Product Specification